Jak działa separacja odśrodkowa

Separacja odśrodkowa znajduje zastosowanie w wielu branżach, takich jak spożywcza, farmaceutyczna, morska, energetyczna, uzdatnianie wody i oczyszczanie ścieków. Pozwala oddzielać ciecz od cieczy oraz ciała stałe od cieczy, aby uzyskać czystsze substancje, odzyskiwać cenne produkty uboczne i ograniczać ilość odpadów. Na przykład: oddzielanie oliwy z pasty, klarowanie zbioru komórek, oczyszczanie paliwa do silników statków czy pozyskiwanie biopaliw z odnawialnych surowców roślinnych.

Różne technologie separacji

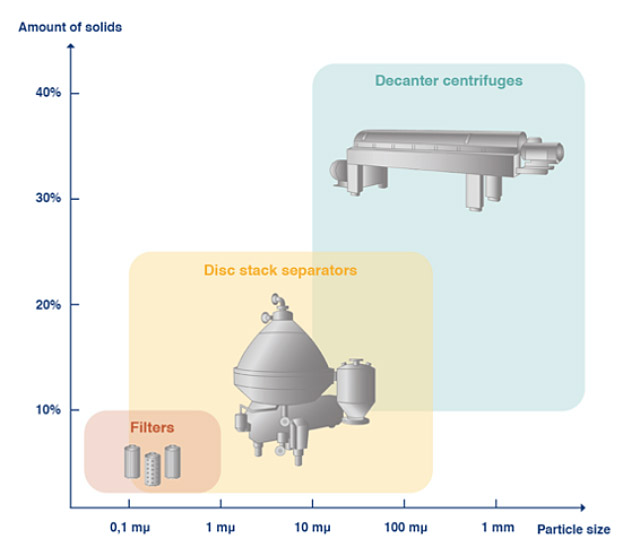

Istnieje wiele metod oddzielania faz ciekłych i ciał stałych od cieczy. Najczęściej stosowane to separacja odśrodkowa i filtracja. Dekantery oraz separatory talerzowe (wirówki) to rodzaje separatorów odśrodkowych. W wielu procesach dekantery, wirówki talerzowe i filtry są łączone - na różnych etapach lub w serii - by osiągnąć wymagany efekt.

- Dekantacyjne wirówk wykorzystują siłę odśrodkową do usuwania dużych cząstek z zawiesin lub cieczy o wysokiej zawartości ciał stałych. Mogą także rozdzielać dwie fazy ciekłe o różnych gęstościach.

- Separatory talerzowe stosują siłę odśrodkową do rozdzielania cieczy o niższej zawartości ciał stałych i mniejszych cząstkach. Skutecznie oddzielają dwie fazy ciekłe oraz fazę stałą.

- Filtry membranowe radzą sobie z niską zawartością ciał stałych, wychwytując najmniejsze cząstki. Zazwyczaj usuwają cząstki do 1 mikrona z cieczy o zawartości ciał stałych do 5%.

Zakresy każdej technologii:

- Dekantery: ciecze z ≥15% ciał stałych, cząstki >10 mikronów

- Separatory talerzowe: ciecze z <25% ciał stałych, cząstki 0,1–150 mikronów

- Filtry: ciecze z ≤5% ciał stałych, cząstki <1 mikrona

- Filtry membranowe: ciecze z ≤5% ciał stałych, cząstki do 1 mikrona

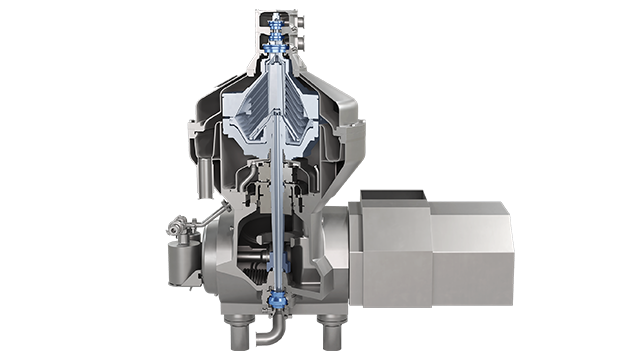

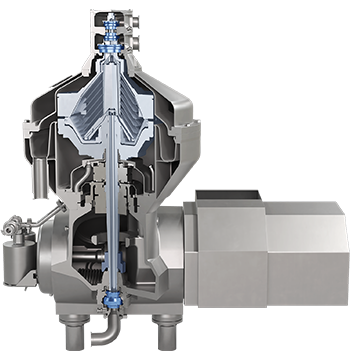

Jak działa wirówka talerzowa

Technologia separacji z wykorzystaniem separatora talerzowego (wirówki) polega na odwirowaniu, podczas którego różne fazy ciał stałych i cieczy są rozdzielane na podstawie różnicy gęstości.

Innowacyjny separator

Chcesz dowiedzieć się więcej o naszych innowacjach w technologii separacji? Kliknij na poniższy link. Alfa Laval wynalazła pierwszy separator talerzowy i od ponad wieku jest liderem w rozwoju technologii wirówek. Cieszymy się, że możemy podzielić się z Tobą wiedzą, którą zdobyliśmy w tym czasie. Odwiedź naszą bazę wiedzy Separator Innovator, aby dowiedzieć się więcej o postępach w separacji i krokach podejmowanych przez Alfa Laval w celu dalszego rewolucjonizowania technologii.