Monitoring

We help you collect, analyze, and manage data from your equipment using smart sensors and analytics to track performance and detect early signs of wear or failure.

What you get

Reliable insights and early warnings to help you act before problems escalate.

FAQs

Find clear answers to the most frequently asked questions about monitoring services.

Monitoring

Performance monitoring

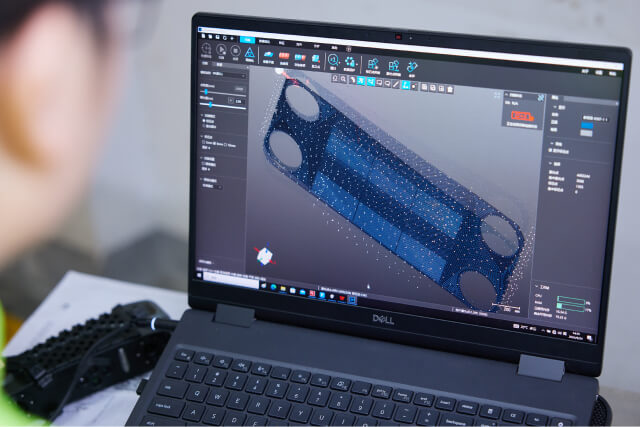

Performance monitoring tracks how well your equipment is running in real-time. It analyzes output, energy use, and overall efficiency. These real-time insights help you spot problems early and find performance optimization opportunities.

Condition monitoring

Condition based monitoring keeps an eye on the health of your equipment. It measures signs of wear, so you can catch issues early and avoid unexpected breakdowns.

Reliable service, wherever you are

We bring you peace of mind by ensuring greater uptime to maximize your productivity and return on investment. Wherever you are, and whatever you need, our global service network supports you with parts, assessments, and expertise. Get in touch with us now and we will get back to you shortly.