Aalborg MX

Aalborg MX is a compact shell and tube heat exchanger with U-tubes, ideal for heating of oil or water. The heat exchanger uses either steam or thermal oil as heating medium.

Type

Shell and tube heat exchanger with small diameter hairpin tubes; either 1/2-pass or 1/4-pass standard configuration. Also available as insert/immersion heat exchangers.

Size

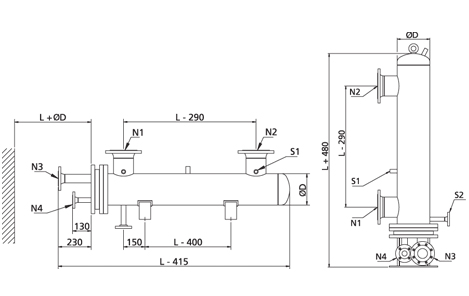

The Aalborg MX (formerly VESTA™ MX) series ranges from Ø100 mm to Ø400 mm shells; straight tube lengths from 600 mm up to 2,000 mm (overall length 980 - 2,700 mm). Standard tubing is Ø10x1 mm, but other types are available. Baffles and nozzles (DIN 86030 or JIS 16K) are tailored to customers' individual requirements and acceptable pressure drop.

Capacity

The heating surface ranges from 0.5 m2 to 64 m2; heat load ranges from 10 kW up to approx. 2 MW. Any intermediate design is available from the standard range. Designs above 2 MW are carried out on request or substituted by another Aalborg Industries product. Design pressure is 16/16 or 30/19 bar(g) and design temperature shell/tube is 160/204 ºC or 195/212 °C.

Fluids

Heating media: water, steam, thermal oil. Heated media: steam, fresh or treated water, thermal oil, lubrication oil, heavy fuel oil, engine coolants, food processing fluids, acids.

Applications

The Aalborg MX series heat exchangers have traditionally been utilized as oil and water heaters in ships' installations but also in a variety of industrial applications thanks to the proven and cost-effective design. Basically, the Aalborg MX series is an extremely versatile design that can be customized to almost any application.

Equipment

The standard shell is fitted with three ½ inch sockets for mounting of safety valve, draining valve, temperature sensor or pressure gauge. A standard outlet tube for mounting of sensor (hydrostatic or electric temperature sensor) for the control valve and additional sensors is also available. When steam is used for heating a standard steam trap is included in the delivery on request.

Approvals

The Aalborg MX series is approved by ABS, BV, CCS, DNV, GL, KR, LRS, MRS, NK and various Scandinavian industrial authorities (Arbejdstilsynet/Denmark, SAQ/Sweden, and TTK/Finland).

Delivery

Alfa Laval Aalborg can deliver any Aalborg MX series heat exchanger within 6 weeks from receipt of order on FCA Aalborg basis. Emergency deliveries within few days for standard types.

Warranty

Alfa Laval Aalborg offers 12 months operating warranty on heat exchangers; maximum warranty is 18 months from time of delivery.

Features and benefits

- Shell and tube design with small diameter U-tubes

- Marine and industrial applications with fluids such as steam, fresh or treated water, thermal oil, lubrication oil, heavy fuel oil, engine coolant, food processing fluids, acids

- Flexible design with customization facilities, adaptable to all applications

Design Data

- Heater capacity range: 10 - 5,000 kW

- Shell diameters/lengths: Ø100 - 400/660 - 2,700 mm

- Design pressure shell/tube: up to 30/16 bar (g)

- Design temperature shell/tube: up to 195/212 ºC

- Materials: Tubes: carbon steel

Shell: carbon steel

Zasada działania

All dimensions are a guideline only. Dimension drawing will be produced upon request.

Mechanical and electronic regulation equipment for Aalborg MX steam and thermal oil heat exchangers

Download information sheets about the mechanical and electronic relutaions in the documentation

The regulation system for the Aalborg MX heat exchanger is supplied as a number of components sized according to the application and applies to either steam or thermal oil operation.

The control system is designed with a sensor in the outlet of the heated medium and a thermostat operating a valve. The desired outlet temperature is set on the thermostat. Fluctuations in flow will result in changes of the measured temperature and thus the signal to the thermostat which in return will further open or close the steam valve or the thermal oil flow.

The system is very reliable and used where it is essential that the temperature is kept constant at all times. To secure both stable and reliable operation a cooling unit for the valve motor is included.