SB Self-cleaning CO2 - zawór do CO2

Samoczyszczący zawór CO2 Alfa Laval SB jest zaworem samoregulującym, który kontroluje przepływ dwutlenku węgla przez systemy zbiorników górnych i inne. Przeznaczony do stosowania w browarnictwie, przemyśle spożywczym, mleczarskim i napojów, ten połączony zawór do ucieczki gazu/zasilania ułatwia odpowietrzanie lub utrzymywanie ciśnienia w zbiorniku. Zawór może być zintegrowany z systemem SCANDI BREW®.

Safe, reliable operation

The straightforward design of this gas management valve, featuring an internal polypropylene valve body and stainless steel spring, provides long-lasting operation. By minimizing the risk of overpressure or underpressure, the valve contributes to safe, reliable operation and maximum uptime.

Hygienic self-cleaning valve

Manufactured of AISI 316L stainless steel, the valve features a special drilled opening in the valve body, which effectively cleans all valve parts during Cleaning-in-Place (CIP). This minimizes the risk of contamination. Alfa Laval 3.1 traceability certification is also available upon request.

Product benefits

- Safe, reliable operation

- Cost-effective hygienic design

- Straightforward installation

- Easy to clean

Katalog produktów

Zasada działania

Construction

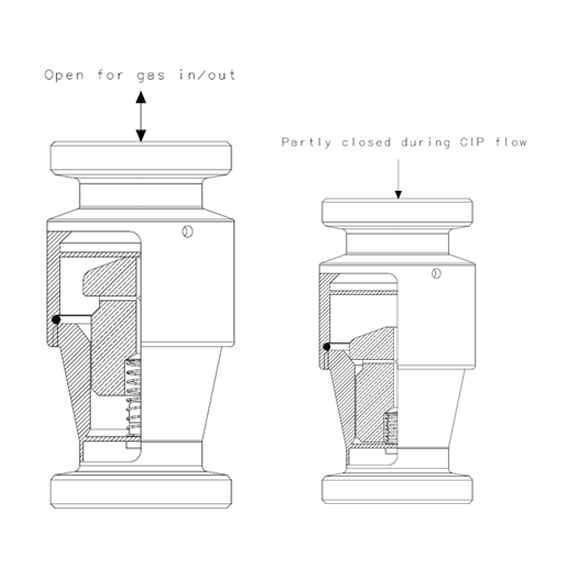

The valve consists of an AISI 316L stainless steel valve housing, spring, plug and EPDM seal. The valve housing consists of two components held together by a threaded connection. Inside there is a valve body made of polypropylene and a stainless steel spring to keep the body in open position.

The valve is typically positioned as an integrated part of the gas/CIP pipe at the top plate. It can be mounted at an angle of 45° (maximum) to the ideal vertical position. It can also be integrated with a SCANDI BREW® tank top system.

Operating principle

The stainless steel spring forces the valve body open, enabling the full flow of gas to pass through the valve in both directions. To force the valve body into closed position, CIP fluid flows in a countercurrent direction against the spring. Due to the force of the liquid, the valve closes. A special drilled opening in the valve body ensures hygienic cleaning of all valve parts.